Discover how Zara turns data into sales with Data Intelligence. A real case of retail success, operational agility and competitive advantage.

A Coruña, spring 2025. While the big fashion houses display their collections on the catwalks of Milan or Paris, Zara remains on the sidelines. Zara doesn't need big shows or a red carpet: its catwalk is the world.

Every store, every click on its app, every garment that disappears from the rack leaves a trace. And that trail —processed in real time by a data analytics system as precise as it is relentless— dictates what is designed, what is manufactured and what is distributed. No guesses. No empty predictions. Just data intelligence.

Zara hasn't just transformed the way we consume fashion. It has completely redesigned the architecture of the textile business. And it has done so with an invisible but flawless tool: data intelligence at the service of every decision.

In Zara, data is not a plus, it is the driving force. It is no coincidence that the average Zara customer visits its stores 17 times a year, a frequency unheard of even for luxury brands— or that the Inditex group has become an empire worth more than $16.5 billion, admired by both its customers and its competitors.

How has a company born in Galicia revolutionized the global fast fashion sector with margins that others can only dream of? The answer is data intelligence.

Real-time Data Intelligence: Fashion is measured by data, not trends.

Source: Inditex

In the traditional fashion industry, production decisions are based on seasonal calendars, runway forecasts and trends. But at Zara, data is the source.

Zara learned a long time ago that if data is used with intelligence, —what is known in the data world as smart data,— one makes smart decisions (data-driven decisions); and their success is the proof.

Before the explosion of fast fashion, Zara revolutionized the fashion world with an idea that was contrary to what most big brands were doing: fashion is created from the present, not the future.

Each of its more than 6,000 stores streams data in real time to the corporate BI systems, capturing millions of operational data points: items sold, returns, inventory levels, shelf time, app interactions, staff feedback, and more.

This global flow of information feeds into a centralized data intelligence platform in Arteixo (Galicia), where designers, product managers, and logistics specialists continuously monitor KPIs through dynamic, interactive dashboards.

Zara's corporate reports are updated hourly. They show which items are selling, which sizes are sold out, which colors are less popular, which stores are asking for more replenishment, and so on. And not only that: they also integrate customer comments, reviews, social media data and store staff observations, collected on mobile devices connected to the Inditex intranet.

For a company like Zara, reacting fast is essential. Powered by its data intelligence strategy and real-time data analytics, the brand can design and launch a new product in days. This is possible because its retail data analysis goes beyond being merely descriptive. It is predictive, actionable, and directly connected to decision-making.

This agility has been crucial to Zara’s success, enabling the company to bring a new product from concept to production in just 10-15 days, compared to an industry average of around 150 days.

How to Leverage Your Data Like Zara?

In the e-book "Data-Driven Decisions: 8 Keys to Data-Driven Decision Making" you will find a defined framework for building an effective data strategy.

Ebook: Data-Driven Decisions

Learn the 8 essentials for making data-driven decisions with this free e-book.

Analytics-Driven Design: When Data Gets Creative

When we think of the skills of a fashion designer, creativity is the first thing that comes to mind. However, at Zara, creativity comes from data.

Zara has more than 350 designers, but their creativity does not bloom from inspirational moodboards, but from data-driven dashboards. Zara doesn't create trends, they interpret them.

On a daily basis, their experts analyze:

- Sales by model, color and size.

- Qualitative feedback from store staff.

- Mentions on social networks, especially Instagram, TikTok and WeChat.

- Emerging keywords in search engines.

Design decisions are guided by micro-demand logic. If customers like something, they produce more; if they don’t, it vanishes. There is no room for nostalgia in the process, only data-driven decisions.

This approach allows Zara to tailor its global collection to local micro-trends in real time. A blouse might become a bestseller in Rome while disappearing from Berlin in the same week. Far from being a mistake, this reflects a process of continuous optimization powered by customer insights.

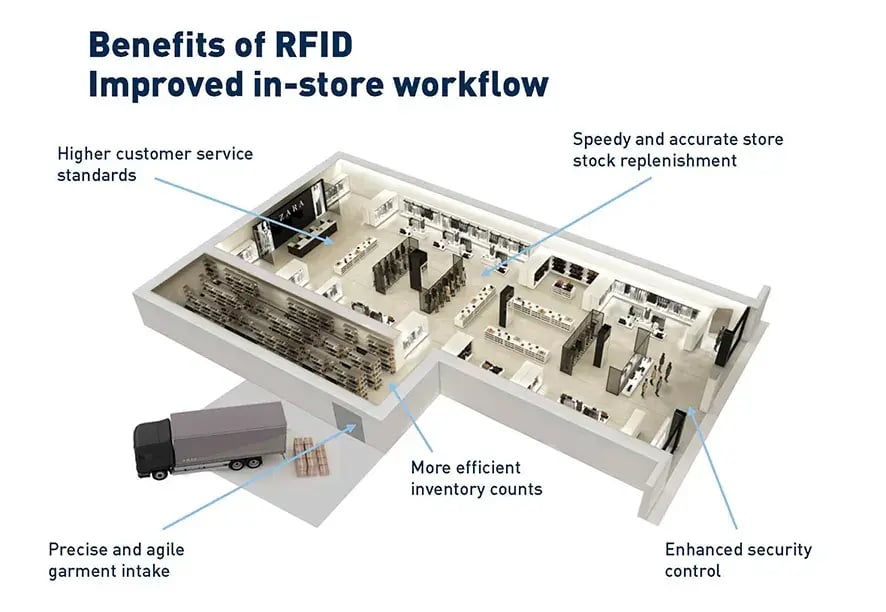

The Chip That Knows Everything: Automation and Traceability With RFID

Zara started experimenting with RFID (Radio Frequency Identification) in 2005, but it wasn’t until 2015 that the system was fully rolled out across the entire chain.

The impact was immediate: sales grew by 17% in just the first six months, fueled by more accurate inventory management, full item traceability, and a faster, more agile response to demand.

Zara’s RFID system integrates a tiny chip into each label before the item even reaches the sales floor. Acting as an intelligent sensor, the chip continuously streams data on the product’s journey —from the logistics center to the store, and ultimately to the point of sale— all without human intervention.

But the impact of Zara’s RFID system extends far beyond logistics tracking. It enables the capture of critical insights such as:

- How often items enter and leave fitting rooms.

- The rotation speed of products on each shelf.

- The sell-through rate of each SKU relative to available inventory.

- The exact quantities delivered to every store — with such precision that even two locations on the same street can hold different inventories, tailored to their specific micro-demands.

All of this data is streamed in real time to Inditex’s central data hub, which operates around the clock and consolidates data from more than 6,000 stores worldwide.

Source: Medium

By integrating RFID technology with data intelligence and predictive analytics, Zara has fully automated stock replenishment. Manual counts are now a thing of the past: algorithms instantly detect when products are running low and trigger replenishment from the nearest logistics centers, optimizing both costs and delivery times.

This advanced traceability model, powered by real-time analytics, not only boosts operational efficiency but also minimizes the risk of overproduction.

The level of data granularity makes it possible to anticipate customer behavior, design new collections based on the performance of previous models, and fine-tune the product offering to the specific needs of each store.

Zara doesn’t just track items, it tracks behavior patterns. And that predictive capability, according to industry estimates, has helped the company avoid hundreds of millions in surplus costs by producing only what customers truly want and are willing to buy. In today’s retail landscape, each RFID tag is no longer just a logistics tool; it has become a strategic decision point.

Omnichannel Experience: Where Digital and Physical Move in Sync

Source: Inditex

Zara has not only reinvented fashion; it has also redesigned the shopping experience. In a sector that for years separated the physical from the digital, Zara went for a fully integrated model between physical stores and e-commerce, where each channel amplifies the other and the customer is at the center of every decision.

This strategy —strongly noticeable since 2017— has allowed the company to offer an omnichannel customer experience, where the customer can buy, return or exchange indistinctly in store or online, with a fluidity that few brands have managed to replicate.

In 2017, online store visits exceeded 9 million per day, the group's websites recorded more than 2.4 billion visits, and peaks of up to 249,000 orders were reached in an hour.

"In 2017, our online sales grew by 41%, accounting for 12% of total sales across all markets with an online presence." - Inditex

But the real value lies not just in the numbers, but in how Zara manages scale. To shorten wait times and enhance customer satisfaction, the company launched its first Automatic Pickup Point in A Coruña, a system that delivers online orders within seconds of scanning a QR code or entering a PIN. This model, now replicated internationally, has transformed order collection into a truly frictionless customer experience.

Omnichannel integration has also taken shape through ephemeral concept stores in cities like London, Milan, and Tokyo, dedicated exclusively to online shopping, returns, and pickups. These spaces not only streamline service but also merge intelligent logistics with experiential design, proving that at Zara every customer interaction is anticipated, measured, and refined down to the smallest detail.

Behind this operational sophistication lies something less visible but equally powerful: a customer service ecosystem spanning more than 40 contact centers, where millions of queries are resolved each year through channels such as social media, chat, email, and phone. The outcome? A 95% resolution rate, achieved thanks to teams highly trained in products, systems and processes.

At Zara, customer experience is not a department, it is a cross-functional strategy built on technology, data, and an operational data-driven culture. In this model, customers don’t have to choose between physical or digital; they decide when, where, and how they want to interact, and they always receive an immediate response.

The Supply Chain That Thinks (And Decides)

According to the company’s official data, 49% of the factories that process its products —cutting, sewing, dyeing, and more— are located in four nearby countries: Spain, Portugal, Morocco, and Turkey. This proximity not only shortens shipping times but also allows production to be fragmented into smaller, more flexible batches.

Instead of producing 100,000 units of a dress and hoping it sells, Zara releases just 5,000 to test the market. If it performs well, production scales up; if not, the item is gone. The entire process is driven by demand-forecasting algorithms that combine historical data, real-time customer behavior, and broader data intelligence trends to optimize the supply chain.

Zara’s logistics is integrated with its operational business intelligence systems. Planning algorithms decide everything from which distribution center each garment ships from to how new production batches are prioritized, all guided by predictive analytics applied to variables such as:

- SKU turnover rates

- Regional sales variations

- Stock-out alerts

- Margin impact per unit

At the logistics hubs in Zaragoza and Arteixo, robots sort and load orders that reach destinations worldwide in under 48 hours. Their work does not follow fixed routines; instead, they adapt to shifting priorities defined by the system.

These models —similar to advanced forecasting platforms— decentralize decision-making while keeping it aligned with global efficiency goals.

As Harvard Business Review claims, Zara is not just a fashion brand; it is a technology company with a textile plant as its interface.

Data Intelligence With AI: Employees That Talk to Data in Real Time

Source: Wear It

One of the most impactful innovations in Zara's model is the democratization of data analytics. The company is implementing conversational BI tools that allow any employee to query the system in natural language.

This means that a store manager can ask an intelligent system:

"How many units of the 5020/123 coat were sold in Barcelona this week?"

And instantly get a visual report, with no technical knowledge required.

These questions, which used to require a consultation with the BI team, can now be answered directly by a regional manager or a design manager using a "Data Chat" type assistant, according to sources in Inditex's technology environment.

Thanks to this approach, Zara has turned business intelligence into a transversal competence, not limited to the data department. This allows employees to make faster and better informed decisions at all levels. Data no longer belongs to one department, but to the entire organization.

Learn how to put data at the center of your organization by downloading this e-book on Data-Driven Decisions and how to prepare your company in the field of data to make smarter decisions.

Data-Driven Culture: It’s Not Technology, It’s How You Use It

Zara’s true differentiator isn’t just its robust technology infrastructure; it’s its data-driven culture. The company has one clear obsession: responding to the real customer, not an imagined “ideal” one.

Every process, from design to logistics, is built to measure, learn, and adjust in short cycles. This mindset ensures that real-time data analysis is not an end in itself, but a practical tool for faster, more effective decision-making.

In the words of Pablo Isla, former CEO of Inditex:

"It's not just about having information, but knowing what to do with it at the right time."

Source: Inditex

What does Zara have that other companies don't have?

Many brands have experimented with BI and predictive analytics, but few apply them with the speed and depth that Zara does. Why?

- Because not all operate under a verticalized model, where design, production, and sales coexist under one roof.

- Because not all rely on a modular, small-batch production structure.

- And above all, because few have built a culture where data drives action rather than serves as justification.

Zara invests less than 0.5% of its revenue in IT, yet maximizes returns by transforming every piece of customer data into a micro-segmented decision. This level of efficiency is nearly impossible to replicate without rethinking the entire organizational architecture.

What lessons does Zara have for other industries?

The Zara case is the perfect example of how business intelligence and real-time data analytics can completely transform a business model. Some extrapolable lessons:

- In food retail: segmenting assortments and promotions by store improves margins.

- In tourism: adapting prices and services to booking behavior optimizes the experience.

- In manufacturing: detecting production line failures in real time reduces costs of poor quality (COPQ).

- In banking: applying real-time analytics to personalize offers increases conversion.

In all cases, what makes the difference is the ability to capture data, process it and act before it becomes obsolete.

The dark side: fast fashion or fast feedback?

Of course, not everything is perfect. The very agility that has fueled Zara’s success also raises ethical and environmental concerns. While the company produces in smaller batches, the constant product rotation encourages faster consumption and disposal.

Inditex has responded with initiatives such as the Join Life program for sustainable fashion, commitments to reducing its carbon footprint, and enhanced traceability across the supply chain. Still, the debate remains open.

What is undeniable, however, is that Zara’s intelligent use of data has enabled it to produce more precisely, in smaller quantities, and with less waste than competitors that continue to operate under an overproduction model.

Conclusion: data does not dress, but it leads.

Zara has achieved what few brands ever manage: turning data into a strategic compass that guides every decision, from design to final sale. Rather than trying to predict the future, it observes it in real time. And instead of guessing what might work, it listens to what is already happening.

This model not only optimizes costs and accelerates processes, it reduces waste, removes guesswork, and elevates the customer experience on a global scale. Every garment sold —or unsold— feeds a system that learns, adapts, and acts. With less excess inventory, fewer forced markdowns, and reduced unnecessary shipping, efficiency naturally translates into sustainability.

In an industry where the noise of trends often drowns out consumer reality, Zara has chosen to listen to the one language that never lies: the language of data.

With every purchase, every return, every click, the brand recalibrates its offering. And that rhythm —constant, precise, and actionable— doesn’t chase trends; it analyzes them.

Because in the end, Zara doesn’t just dress people. It dresses data-driven decisions.

Ebook: Data-Driven Decisions

Learn the 8 essentials for making data-driven decisions with this free e-book.